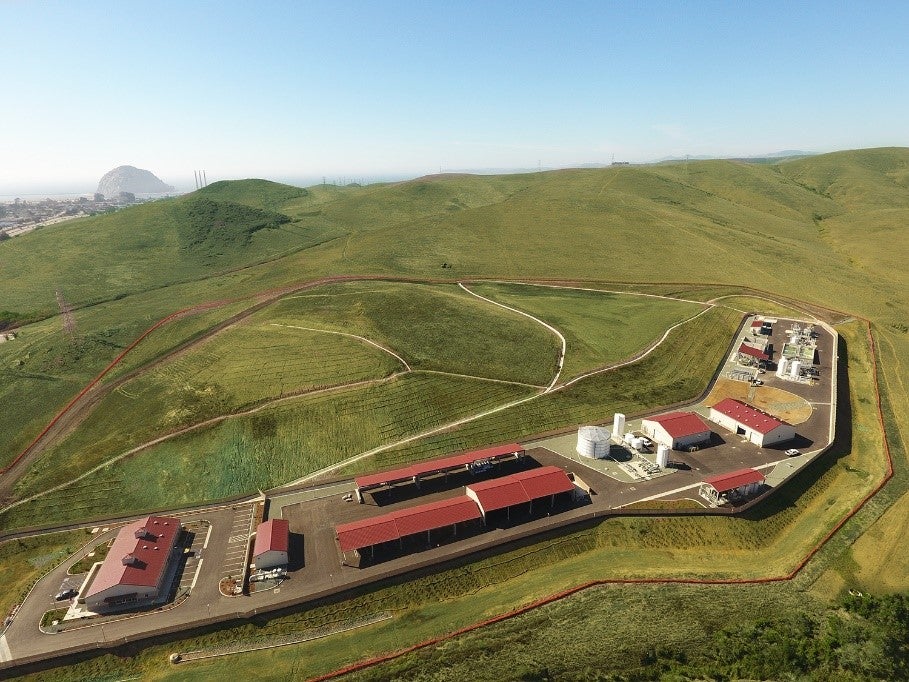

The City of Morro Bay is a vibrant seaside community on the coast of California known for its scenic beaches and Morro Rock, a 576-foot-tall volcanic remnant on the north side of the harbor. This distinctive landmark overlooks Morro Bay, where Los Osos and Chorro Creeks mix with the saltwater of the Pacific Ocean to create a diverse ecosystem that supports many sensitive species and attracts a flourishing tourism industry. Just inland, tucked inconspicuously into a hillside away from tourists’ view, is the city’s new water reclamation facility (WRF). This advanced treatment facility incorporates innovative water reuse, nutrient management, and stormwater filtration solutions that preserve Morro Bay’s sustainability, fortify its resilience, and support its future growth.

Proactively Mitigating Vulnerabilities

The previous Morro Bay Wastewater Treatment Plant (WWTP) was located directly along the coastline, making it vulnerable to flooding from sea level rise; in fact, soon after the new facility was constructed, the old plant was severely damaged in a historic flood event and submerged in five feet of stormwater. Fortunately, the new facility avoided potential ecological and economic disaster.

The city chose to both solve direct flooding concerns and proactively address future water needs by constructing a new advanced treatment facility that had the following goals:

Protect the surrounding environment, tourism activities, and fishing industry by improving the quality of water sent to the ocean outfall.

Relocate the facility away from the flood zone to ensure a safe, resilient, and reliable facility for decades to come.

Produce highly purified reclaimed water for indirect potable reuse (IPR) via injection into the Morro Valley Groundwater Basin, adding a sustainable and local water supply for the community.

Protect the basin from overdraft and contamination from saltwater intrusion.

Keep the bay clean and sensitively address local community concerns.

Taking an Innovative, Cost-Saving Approach

The City of Morro Bay was committed to keeping costs down for the community and chose the design-build delivery method to maximize potential for innovation and cost savings. Black & Veatch, as part of a design-build joint venture with J.R. Filanc Construction, proposed a biological nutrient reduction (BNR) with membrane bioreactor (MBR) system that was more cost-effective than competing sequencing batch reactor (SBR) technologies while producing higher quality effluent to further the city’s goal of protecting the marine environment. The Black & Veatch/J.R. Filanc Construction joint venture team was responsible for the following scope:

New headworks

Nutrient treatment including fine screens, BNR, and MBR

Stormwater and peak flow direct filtration

Indirect potable reuse (IPR) system consisting of reverse osmosis (RO) and ultraviolet advanced oxidation process (UV-AOP) utilizing chlorine as the oxidant

Calcite contactor remineralization

IPR storage tank and chlorine contactor

Infrastructure for an overall advanced water treatment facility, including pump stations for both IPR and ocean outfall discharge

Chemical storage and metering facilities

Solids handling facility with belt filter press dewatering

New administration and operations facility

Construction of operations and maintenance buildings, storage yards, and buildings to centralize various water and wastewater groups into a single modern facility

The city’s unusually high peak flow factor would normally require a costly flow equalization basin (FEB) for sporadic usage; leveraging Black & Veatch’s innovations in stormwater management, the design included a system to directly filter these flow peaks and blend the filtered effluent with the high-quality effluent from the MBR system. This stormwater adaptive filtration equipment (SAFE) system eliminated a five-million-gallon FEB and reduced the size of the BNR with MBR system by 30 percent. Overall, this approach saved over $7 million in construction costs with significant ongoing savings in operational costs. This project is the first MBR facility permitted for IPR in California and will support the City of Morro Bay’s local water resiliency for a growing population.

In addition to making the SAFE system approach possible, the use of an MBR system enabled advanced IPR treatment without needing a second micro-filtration/ultra-filtration (MF/UF) pretreatment. The team evaluated several potential hollow-fiber systems to select the best supplier that would provide the City of Morro Bay with reliability, proven expertise, implementation experience, extended warranty provisions, membrane cartridge replacement costs, and key manufacturer differentiators. This early selection enabled the Black & Veatch/ J.R. Filanc Construction team to optimize the detailed design and drive further savings. The use of MBR to eliminate MF/UF pretreatment of water for the IPR system saved over $4 million in construction and operational costs.

Rather than flatten the site as is typical for similar facilities, our team took inspiration from the surfers near Morro Rock and designed the plant to “surf” the topography of the hillside. The plant was designed to balance earthwork, utilize the natural fall of the site, and drive most of the hydraulic flow by gravity—eliminating the need for intermediate pump stations and associated construction costs and operational complexities. These innovations saved the city another $3.5 million as well as countless truck trips through the city by eliminating the need to off haul soil.

“We are proud to be a leader in use of this [MBR and IPR] technology to support California’s move toward more sustainable water supplies.”

-- Gregory Kwolek, Director of Public Works, City of Morro Bay

Overcoming Challenges and Looking Ahead

The Black & Veatch/ J.R. Filanc Construction team was awarded the Notice to Proceed (NTP) for construction in March 2020, just as the COVID-19 pandemic began to shut down operations, delay permitting, and cause severe supply chain and labor shortage issues. The separately contracted construction of the pipelines connecting the WRF to the city infrastructure was also paused due to unforeseen conditions including environmental permitting delays and the discovery of cultural artifacts. The design-build team continuously adapted the approach to mitigate these issues while still reaching major project milestones on time, despite an array of operational, permitting, supply chain, and workforce availability challenges.

This foresight and efficiency prepared the City of Morro Bay for what happened next: In January 2023, the old WWTP was severely damaged in a historic flood event and submerged in five feet of stormwater. If the new WRF had not been operational, the City of Morro Bay would have been unable to treat raw sewage, which could have resulted in heavy fines and severe impacts to local water quality and the fishing and tourism industries. Fortunately, due to the city’s proactive strategy to develop the new WRF, plus the design-build team’s efficiency and effectiveness, a potential ecological and economic disaster was avoided.

The new WRF has been operating since October 2022 and the project was completed in March of 2024. Wastewater treatment facilities are typically not able to comply with discharge regulations for weeks to months during project startup and testing, but the new Morro Bay WRF was immediately in compliance and outperformed the design criteria as soon as operations began. Compared to the water quality of the old WWTP, the new WRF produces water with 350 times better clarity and contains only a fraction of the ammonia and other compounds.

As a small community of 10,000 residents, this project was the largest and most ambitious in Morro Bay’s history. The operational robustness and greatly improved water quality will have lasting benefits to plant operations and Morro Bay’s overall ecosystem for generations to come.